cool green

more we now have a little patch of green lawn and some rusty planters to go with our deck. summer is here.

with the amount of high shgc glass on our south facade, it would be easy to overheat without proper shading.

on the hottest days, we simply close our exterior shades to block unwanted solar radiation before it hits the glass. the ability to fully control the shades means we can optimize the amount of gain or shade we are getting depending on the daily conditions.

the shades can be tilted to allow views out while still blocking the sun. the cost of the shades was offset by the elimination of cooling equipment and the cost of the energy to operate it.

the exterior shades combined with the exceptional insulation and thermal mass has kept our house exceptionally cool and comfortable without any air conditioning.

more detail to follow. check back soon.

.32ach

we recently performed our final air-tightness test at skidmore passivhaus with a result of .32ach at 50pa. we are extremely pleased that our clear air-barrier strategy and diligent execution paid off.

here's a snapshot of our final phpp #'s:

there is no doubt that achieving passive house, particularly in our climate, is fairly easily achievable. it does require smart design, careful planning, a contractor that understands and pays attention, and a healthy dose of persistence. if you are ready to build one for yourself, drop us a line at info@insituarchitecture.net.

more pictures and info coming soon.

nearing completion

after almost a year of construction we are excited to say skidmore passivhaus is nearing completion. it's come a long ways since this. here are a few recent shots of the interiors coming together.

more news, pictures, and the details coming soon.

fast forward

suck and blow

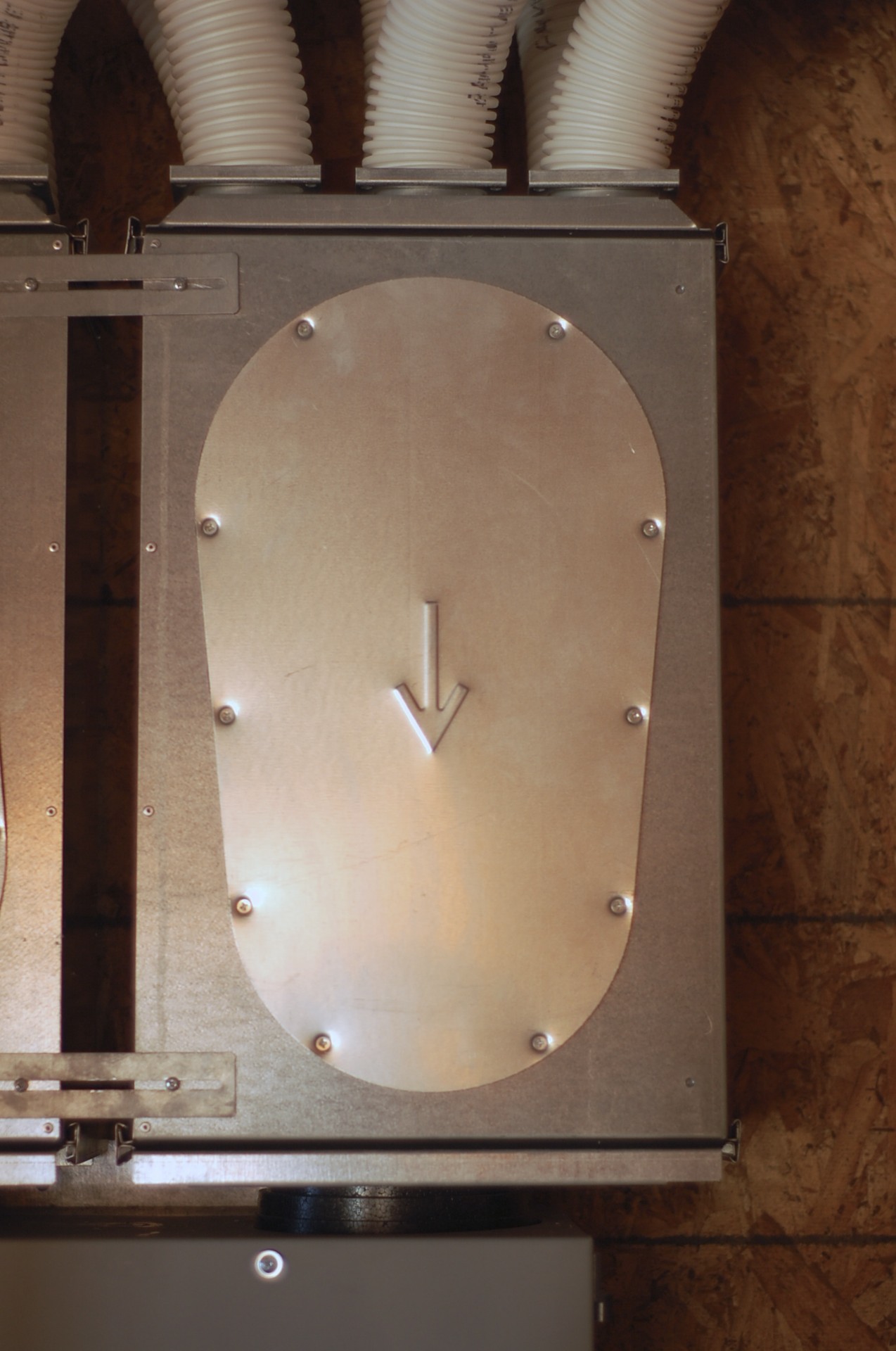

rough-in work has wrapped up on skidmore passivhaus and it's time to look at a few of the features under the hood. this new airtight home (or shall we say leak-free) is equipped with mechanical lungs.

we chose the PH certified zehnder comfoair 200 hrv, capable of producing up to 125 cfm of continuous ventilation. this project requires about 70 cfm (60% setting) to achieve .31 air changes per hour (or roughly 1 air change every 3 hours).

the 3" flexible ductwork is a double-walled proprietary system called comfotube made by zehnder. very easy and fast to install. the goal is to keep the runs as short and straight as possible.

the round ceiling rough-in boxes are used for either supply or exhaust air. either 1 tube or 2 tubes are connected depending on the cfm requirements. exhausts are located in the bathrooms (20 cfm continuous) and kitchen (30 cfm continuous). we have 3 exhaust locations - each with 2 tubes. there are 4 supply locations.

supply air is typically provided at the ceilings but we have a low supply register in the double height living room.

the tubing terminates in the ceiling of the mechanical room. 6 supply tubes and 6 exhaust tubes. manifolds gather the supply and exhaust tubes respectively and connect them to the unit.

exhaust air flows through the machine, the heat is captured in the core, and the air is expelled to the outside.

fresh air is brought into the machine from the exterior, and warmed by the heat captured from the outgoing air. the zehnder is about 92% efficient and uses just 7.1 watts / cfm.

the fresh air supply and exhaust are ducted in well insulated metal ductwork from the bottom of the unit to the exterior. the fresh air supply is located high on the exterior wall with the exhaust about 10' below. the duct penetrations were carefully air sealed to the plywood air-barrier. this unit also requires a condensate drain that we've tied with an air gap into the kitchen waste pipe.

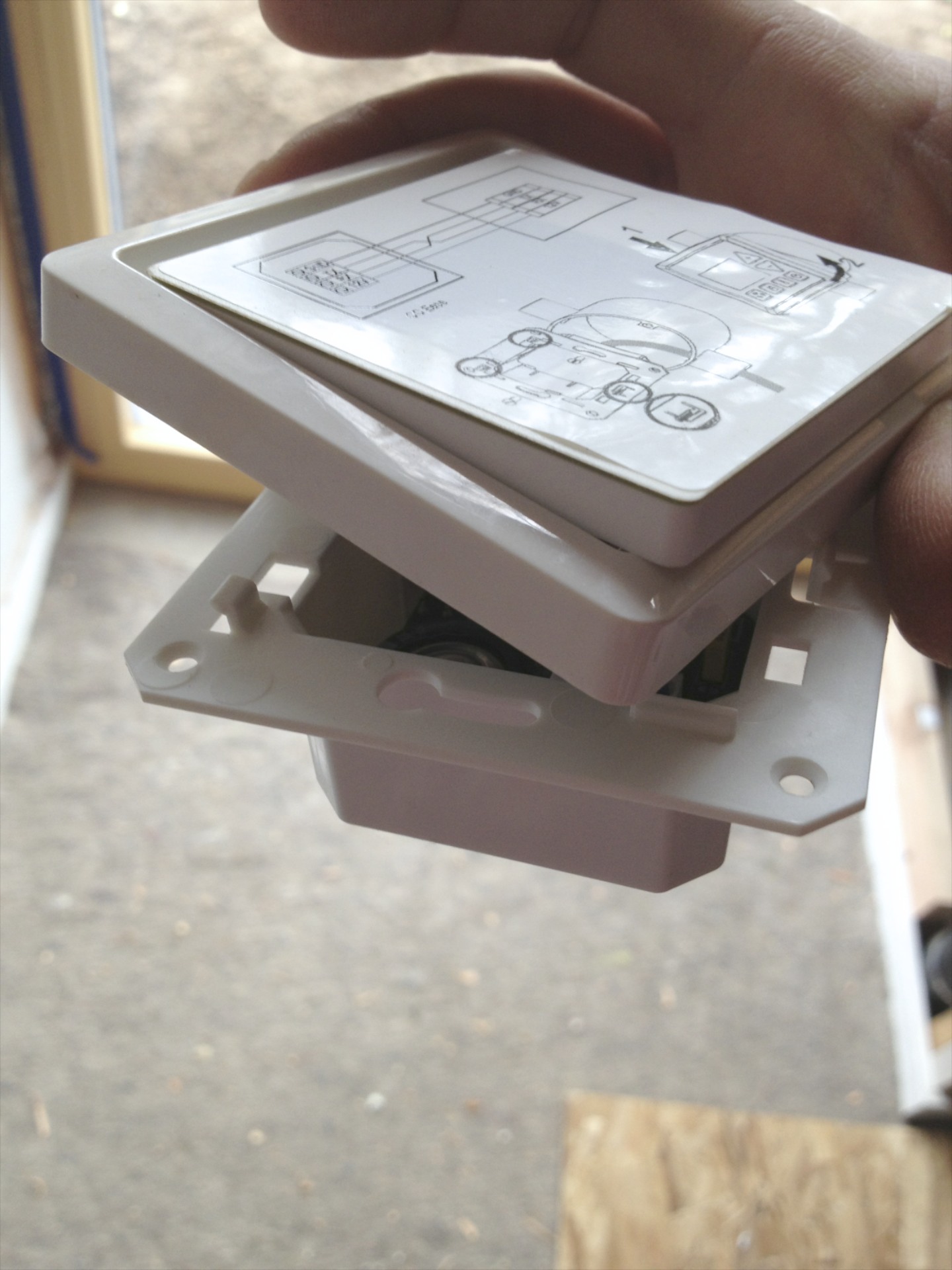

the main controller will be located in the kitchen, providing the ability to boost the ventilation rate temporarily to 35 cfm while cooking. each bathroom will have a timed switch to boost the rate to 24 cfm if needed after a shower. we also conveniently have an operable window located in the kitchen and both showers.

thanks to IM Plumbing for help with the installation, and to Matt Grove from Zehnder for help with the design.

sheetrock has wrapped up and painting has begun. check back soon for more.

blow

stained cedar siding

siding work has mostly wrapped up. the vertical siding is installed on rainscreen over rigid exterior insulation. see this past post for more info on the assembly. here's a first look at the siding pretty much completed.

the siding is off the shelf 1x6 channel made from tight knot cedar. it's stained with 1 coat of olympic semi-transparent stain in ebony.

the large south windows (and doors) have exterior motorized aluminum sun shades supplied by hella. the siding has been detailed to allow the shades to stack in recessed pockets. in this photo the shades are down about 9 inches and just visible on the 2 living room units (lift / slide door and fixed upper unit). more on the shading later.

the "breezeway" features a south facing door / window with a wood canopy (to be painted black) topped with clear tempered glass.

the entry door at left features acid etched glass for privacy and has a smooth accent panel adjacent that will be painted a deep red. the wood canopy will painted black and features a simple galvanized metal pan roof. steel rod will be used to hang the canopy from a bracket mounted to the wall above. a mahogany deck will eventually complete the front porch.

the north street facade also features a narrow smooth accent panel that will be painted with the same deep red. the same siding runs horizontally to form an accent between floors.

check back soon for more.

pre-certified

going solar

the rare sunny portland winter day has allowed us to regale in the golden rays.

glorious sun reaches all the way to the back of the kitchen.

the south facing windows / heaters are working.

the studio flooded in mid-day sun.

the breezeway will be a study in light and dark.

rejoice.

in addition to direct gain, we will have a small PV system on the roof. more on that later.

stair progresses

while most of the attention has been focused on the insulation, windows and air sealing, the interior stair has made slow but steady progress.

stringers are tube steel bolted to concrete landing and wood wall

tread risers are 1/8" thick bent plate steel

everything is fit up and welded in place

guardrail is 1" sq tube steel verticals

steel will be left natural with all the signs of fabrication exposed

a clear coat will be applied at completion

still more to go but we think it's coming along nicely.

thanks to alameda metal works for their fine work.

thermal bridge free exterior

next up on skidmore passivhaus is installing the outsulation on the walls along with the rainscreen furring.

the plywood sheathing was first covered by a weather resistive barrier with metal head flashings at the windows and doors.

most walls get a layer of 3" poly-iso, while the south wall will get 4" to match the recessed pocket for the exterior shades.

2 screws (with plastic washer) per 4x8 sheet hold it in place until the furring strips are installed.

all seams and fasteners are taped. the face of the insulation is treated as a second weather resistive barrier.

additional flashings at all doors and windows will be taped to the insulation as the wood trim is installed.

1/2" x 2" pt plywood furring strips run vertically to create the drainage plane. they are held in place by just a few fasteners until the next layer is installed.

since we are using vertical siding, a second layer of furring runs horizontally. we used pt 1x4 as a solid nailing base for the siding.

long fasteners secure the second layer of furring strips running horizontally through the foam to the studs. the straightforward framing layout makes the studs much easier to locate.

keep in mind that long fasteners get expensive. we settled on grabber #10 x 6" square drive coated screws (from nw staple).

next up on the exterior is trimming windows and installing siding.

stop by again soon.

foundation foam

while there's a lot of talk these days about building without foam, we decided early on to use continuous rigid board foam outsulation for this project. to begin the foundation gets 4" of expanded polystyrene.

these 8' long pieces are held in place at the bottom by backfill and at the top by concrete spikes. spray foam was first applied to the back of the pieces to fill gaps and help secure them.

the concrete spikes are recessed into the foam to minimize thermal bridging. only 3 spikes were used per 8' long piece.

step 1: use hole saw bit and pry out hunk of foam.

step 2: use hammer drill to drill hole in foundation.

step 3: prepare 6" concrete spike and plastic washer. (concrete spike from dealers supply / plastic washer from service partners supply)

step 4: hammer spike and washer to secure foam.

step 5: spray foam any gaps

step 6: reinstall foam plug using spray foam as adhesive

when the weather warms we will be applying a cementitious coating direct to the foam to provide the finished surface. after final grading, only 6" or so will be exposed to view.

waiting for guffman (or looking through windows - part 8)

when we began this process, we only had a few rules. one of them was real wood high performance windows. at the conception of this project, we were thinking about making a pretty good house. Super insulated, airtight, with triple glazed windows and a heat recovery ventilator, but not necessarily passivhaus. since we ruled out plastic or fiberglass, US built windows were at the top of the list. once we decided to build to passivhaus, it quickly became clear that we had to look overseas.

our initial pricing was from optiwin, internorn, and pazen. optiwin was very appealing aesthetically but super expensive. internorn provided fantastic pricing, but there was no rep in the US meaning distant communications and pretty much zero support. pazen offers a slightly different product with a fiberglass exterior cladding and more minimal frame profiles, but they only offered a stainless steel clad door. because we had lots of doors, the price jump was huge and they were way out of our budget.

about the same time, our local loewen rep started offering unilux. we visited another local passivhaus project to see them installed, and we were impressed. the pricing was strong, and we felt most comfortable having a rep locally, although they only had a limited understanding of passivhaus. we thought we'd made up our mind, until we stumbled onto zola windows. nearly identical to the german and austrian made passivhaus windows, zola windows are manufactured in poland and offered at a much more competitive price point. we worked through all the options, input the data into PHPP, and scrutinized the sample window section that we got our hands on. it seemed like a good balance between quality, aesthetics, and price point. decision made.

one of the biggest challenges of using european windows is the long lead time (for our order the lead time was estimated at 12-16 weeks). we worked hard to have our window order ready to go by the time we were breaking ground. once we placed the order, the race was on to make sure the house was ready when the windows finally arrived. 18 WEEKS LATER they finally arrived. when we finally opened the container door to check them out, 2 of the biggest units had broken free from their braces and had fallen over at somepoint during shipping. while nothing was catastrophic, there were issues both functional and aesthetic.

fast forward 6 weeks. zola has been super responsive and we're confident that in the end everything will be as good as new. the windows and doors are installed and are beautiful. the house is dry, the first blower door test went well (.44ach at 50pa), and we are steadily moving toward insulation and sheetrock.

here's a quick look at some of the process. first, prepping the rough openings:

step 1 - use pink prosoco joint and seam filler at corners and joints of rough opening.

step 2 - use red prosoco fast flash to coat rough opening and extend approx. 6" out onto sheathing.

to apply these prosoco products, simply lay down a bead from a caulking gun and spread with a cheap plastic spreader. the result is a waterproof, airtight, and vapor permeable flashing without the usual complications of peel and stick flashings. of course no through wall metal flashings on a passivhaus.

next, windows arrive and are unloaded.

not what you want to see when you open the door of the container. i think they forgot to do the ACTUAL bracing at the factory.

some of these units are HEAVY! thank to Doug Marshak and his Awesome Framing Crew for doing the very heavy lifting.

small tilt/turn unit for the kitchen.

Doug and Jesus installing the small window in the 2 story living room.

the big units waiting to be installed.

after a few nervous hours, the biggest unit finally goes in. thanks to Graeme Thomson for the smart hoisting method.

the large fixed unit installed above the lift/slide door.

front door with translucent glass and large window to the street.

breezeway with tilt/turn terrace door and fixed sidelite.

studio with tilt/turn door and fixed sidelite.

check back soon for more as we try to catch up with construction: HRV rough-in, steel stair installation, flashing the windows, installing the exterior insulation, and rainscreen furring.

air sealing

air tight per passivhaus = .60 ach at 50pa. if you don't know the terms or numbers, just know that this is extremely air tight. achieving this requires care and attention to detail, both in the design approach and in the execution.

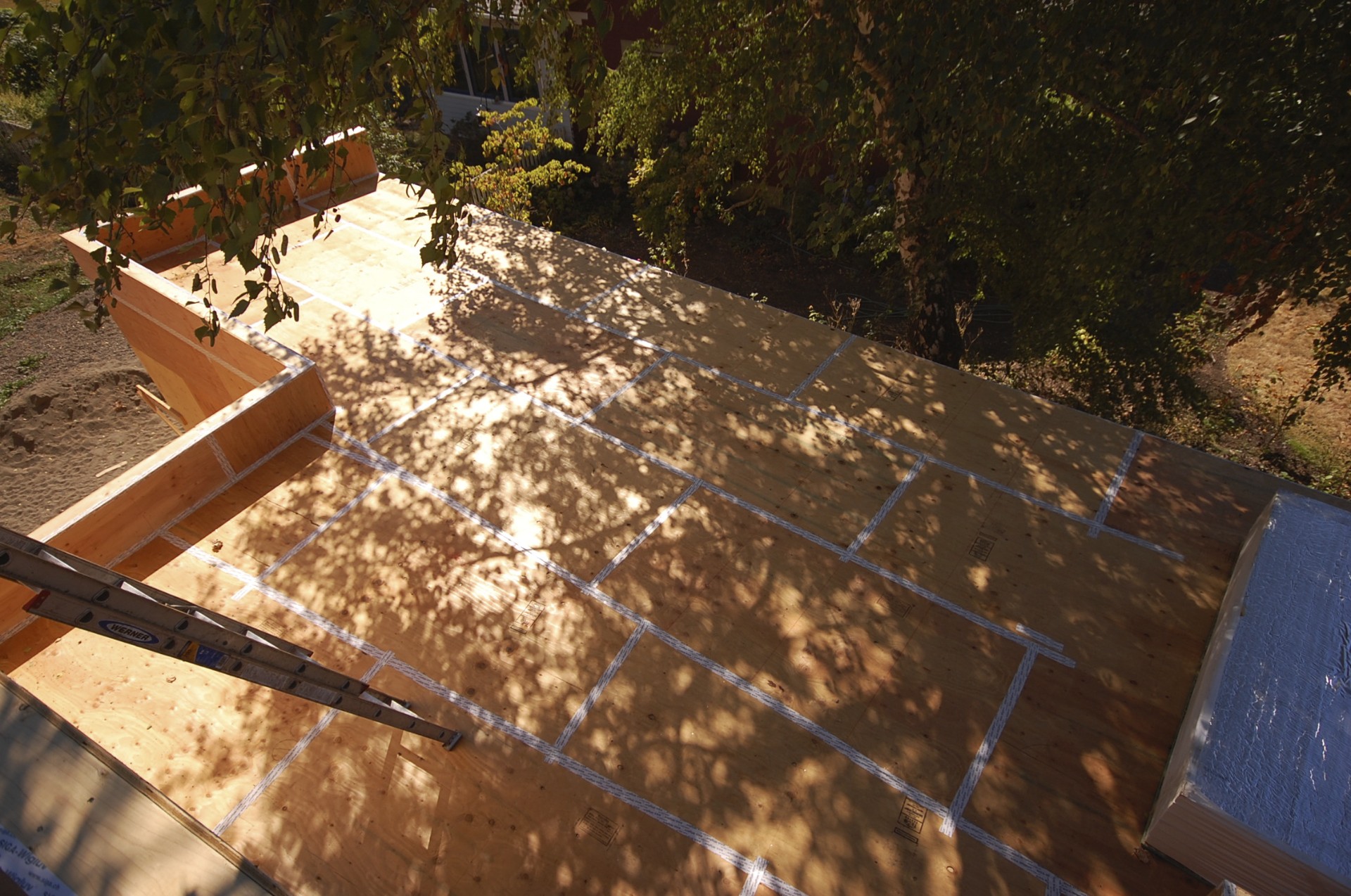

our air barrier strategy is simple - use the exterior plywood roof and wall sheathing as the continuous air barrier. all seams, corners, and joints in the plywood are taped with SIGA wigluv tape.

the sill plate is taped to the concrete foundation (our 2x8 sill is cantilevered beyond the foundation). the concrete is first primed with SIGA dockskin primer to ensure adhesion. carefully apply tape. the result is an air tight joint. simple.

the plywood air barrier runs up the wall and over the roof. the joint is taped and then the parapet is framed on top. after seeing some tears in the tape we got nervous and taped the parapet too.

all roof and wall penetrations are sealed. we used SIGA wigluv for these too.

the tapes are super sticky, very flexible and easy to use. the paper backing is recyclable, which is good because there is a lot.

it's not inexpensive though, and we used far more than we originally thought. air sealing takes time too. it's worth it though.

SIGA tapes are available through small planet workshop.

another great exterior air sealing product is prosoco joint and seam filler (used at rough openings in combination with prosoco fast flash). more on that in the next post.

.44 ach

framing for efficiency

framing has been moving along at skidmore passivhaus since we placed our slab on grade. the house is quickly taking shape thanks to dam framers (doug marshak and crew).

there are a few things that make the framing on this house just a little different from the typical house:

- untreated bottom plates on 30lb building paper

- 2x8 wall studs at 24" o.c. (roof trusses align)

- balloon framed 2 story walls

- upper floor hung from ledgers

- single top plates that interlock at the splices

- open corners with minimal blocking

- open web trusses with sloped top and level bottom

- header free openings (except for the living room doors)

- long walls on plywood module

All of this results in more space for insulation!

Plus there's less wood used and less material cost.

Some of the many next steps include:

- taping the plywood with SIGA to create the air barrier

- installing the single ply membrane roof

- prepping the rough openings with Prosoco Fast Flash

- roughing in plumbing, HRV, and electrical

Check back soon for updates.

council crest update

exterior and interior progress continues.

architecture by bohlin cywinski jackson

construction by don tankersley construction

notes on placing an exposed slab on grade

Here are some quick notes on our Exposed Slab on Grade (placed on top of continuous 15mil vapor retarder and 4" of eps insulation): Placing concrete on a continuous vapor retarder definitely ups the degree of difficulty when it comes to finishing and curing the slab. Water in the slab can only move out the top, meaning the slab can dry unevenly, crack, and even curl. To compensate we are trying a wet "flood" cure.

We decided to use fiber mesh reinforcing and eliminate the steel reinforcing altogether from slab. Apparently the fiber can make finishing trickier, but it typically results in strong slab with less cracking and for a bit less cost.

The type and location of joints is always a question - we even considered for awhile not using them and letting the slab crack more randomly (it will crack). In the end we decided to use a tooled joint (in this case made with a custom tool from another project) and to place them strategically under walls so they are barely visible. Tooled joints can be made almost immediately before cracking can happen whereas sawcuts have to wait until slab is firm enough to handle the saw, and potentially after random cracks have already occurred. Saw cuts also have a risk of spalling, but when they are executed properly they certainly look best.

After knocking around options for curing the slab, we decided to go old school and use a wet flood method. The idea is to cure the slab slowly and evenly by keeping it wet and cool, allowing it to gain as much strength as possible before subjecting it to the stresses that occur when it dries out. The slab edge formwork was already above the top of the slab, so it was relatively easy to keep the slab underwater. It uses a fair amount of water as there are minor breaches in the perimeter formwork dam, but it eliminates the use of expensive chemical curing compounds.

So far we have kept the slab wet for 5 days (flooded most of the time) and we're still babysitting it. It's time to get set up for the last small concrete pour (a plinth for the stair which doubles as a landing), so the wet curing will come to an end. Only time will tell what the result will be, and we'll never know if our methods were better or worse.

breaking ground on skidmore (passive) house

After many many months (years really) of scheming and planning, we finally broke ground on our new house. A lot has happened since our last look at the project in passivhaus progression. It took us a bit of time to get our house ready for sale, but we eventually sold it, found a great house to rent complete with chickens, moved, and are getting settled in our temporary digs. First up was getting our delinquent and non-responsive tenant out of the house. We got our first (and hopefully last) taste of the eviction process. A few checks and a couple of weeks later we took possession and had a close up look at the sorry state of the house. Next we removed some of the existing trees. A few were unhealthy, a few were in or too close to the footprint, and a couple were creating massive shade. While we struggled with this decision and upset at least one neighbor, in the end we decided it was best in the long run to remove the largest Oak in the backyard. It was sad to see it come down but the lot has been transformed back into a sunny paradise and we hope over the next decade to develop a well designed and much more beautiful landscape.

While the first bank we approached about construction financing had favorable rates and seemed easy to work with, the process quickly turned sour as they began to question first the green roof, then the single ply membrane, separate structures, and finally the lack of a garage. In the end it became apparent that they didn't get it and it was time to try another route. At the same time, we decided that the separate structures created some domestic challenges in addition to lowering the value of the property in the eyes of the bank, so we quickly redesigned the house to incorporate the space between the buildings as interior living space. Although it adds more square footage and cost, it does make for a better surface to floor area ratio and had a favorable impact on our PHPP calculations. We then approached a local bank with our revised design complete with green roof, no garage, and modern aesthetic, and it was basically smooth sailing right up to the loan closing. Aside from their annoying tagline, so far I have nothing but good things to say about my experience with my local bank.

The permit process went a little more smoothly. After responding to a simple structural checksheet, answering some questions from the plans examiner about the Passive House specific details, filing a required Operations and Maintenance agreement for the ecoroof with the County, and smoothing out some internal confusion at the city about an existing cesspool tank and drywell, we got our new building permit as well as demolition permits for the existing house and garage. Next up was testing for Asbestos; the demolition contractor was required to have paperwork certifying that the debris was free from Asbestos. Somewhat to my surprise, Asbestos was found in a number of unusual places including window glazing, caulking at the roof penetrations, and drywall compound. Another check and about a week later the Asbestos was abated and demolition could finally begin.

Here's a quick progression of what's happened over the last 2 months:

Trees are cut and asbestos abatement in progress.

House and garage are gone!

Old tanks are decommissioned and building area is stripped.

Building pad is prepped with compacted gravel.

Footings are formed, EPS placed and moisture barrier taped.

Concrete is placed in footings.

Gravel backfill is placed and compacted underslab.

Underslab EPS insulation is getting set on sand bed.

Now that we've started, there's much to talk about. Some possible ideas:

- A better way to build an insulated slab on grade?

- PHPP calculations and optimization of systems

- PH certification: PHIUS+ vs PHA

- Passive House Windows

There are many people to thank for their help (directly and indirectly) in getting us to this point. Here are just a few:

- Aaron and Mike at Brute Force Collective

- Dan Whitmore at Blackbird Builders

- Florian at Zola European Windows

- Don Tankersley Construction

- John Russell (Concrete) Construction

- Matt at Zehnder

- Skylar at Hammer and Hand

- Ryan at Earth Advantage

All for now. Check back soon.

Jeff